|

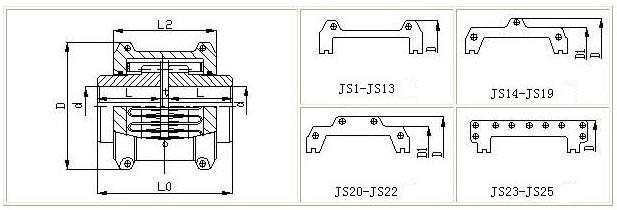

JS type serpentine spring coupling Features and applications: It is a structurally advanced metal elastic coupling. It relies on serpentine springs to transmit torque. Its transmission characteristics and advantages are as follows:

1. Good vibration damping and long service life The coupling is embedded in the two halves by more than 36% in the axial direction of the serpentine spring piece. The trapezoidal section of the serpentine spring piece is made of high-quality spring steel, subjected to strict heat treatment and specially processed, and has good mechanical properties, so that the service life of the coupling is much longer than that of the non-metallic elastic component coupling (such as elastic sleeve). Pins, nylon rod pin couplings) have grown significantly.

2. The variable load range is large, and the two toothed bearings are in contact with the reed. The tooth surface is curved. When the transmission torque increases, the spring piece will deform along the tooth surface to make the two coupling halves. The force acting on the reed is close. The contact point of the reed and the tooth surface, that is, the change of the moment, varies with the magnitude of the transmitted torque, and its transmission characteristic is variable stiffness. Therefore, it can withstand a larger load variation than a general elastic coupling. It can be seen from the following figure that the transmission force causes the cushioning effect generated when the reed is deformed along the tooth arc, especially when the machine is started or when the impact load is strong, to some extent, the safety of the supporting mechanism is protected.

3. High transmission efficiency and reliable operation The transmission efficiency of the coupling is determined to be 99.47%. Its short-time overload capacity is twice the rated torque, and the operation is safe and reliable.

4, low noise, good lubrication The aluminum alloy casing protects the spring from running out during operation, and the shell is filled with butter, which not only makes the lubrication good, but also eliminates the noise when the reed is engaged by the damping of the butter.

5, the structure is simple, easy to assemble and disassemble, the whole machine parts are small, the volume is small, the weight is light, the spring piece designed to be trapezoidal cross-section and the trapezoidal tooth groove are especially convenient and compact, so that the assembly and disassembly and maintenance are simpler than the general coupling .

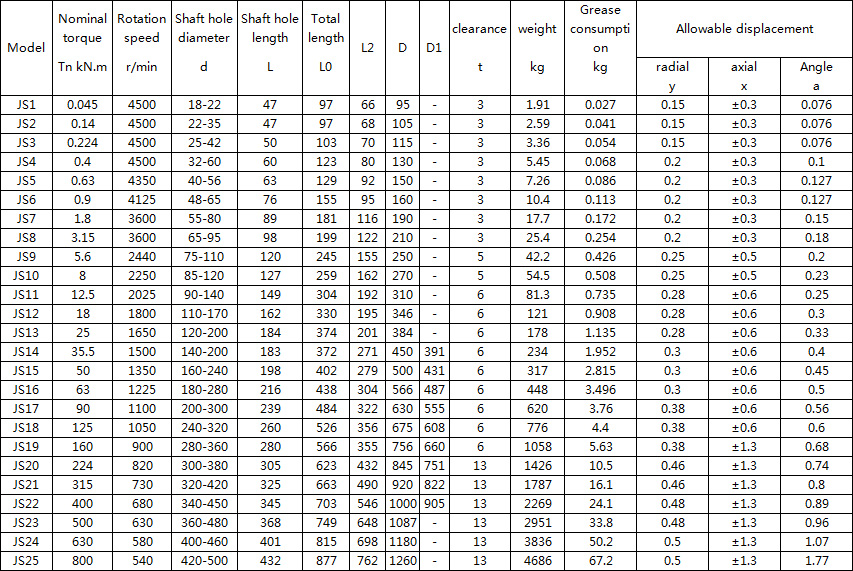

6. Allows for large installation deviation Since the spring piece is in point contact with the toothed surface, the coupling can be made more flexible. It can be installed in normal operation with radial, angular and axial deviations. The specific installation deviation values are shown in the other table.

|

grid coupling

grid coupling

JS grid coupling

Time:18-09-21

grid coupling

JS grid coupling

Time:18-09-21

|

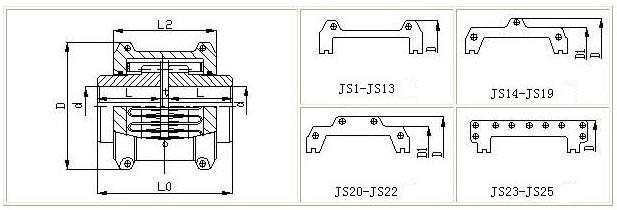

JS type serpentine spring coupling Features and applications: It is a structurally advanced metal elastic coupling. It relies on serpentine springs to transmit torque. Its transmission characteristics and advantages are as follows:

1. Good vibration damping and long service life The coupling is embedded in the two halves by more than 36% in the axial direction of the serpentine spring piece. The trapezoidal section of the serpentine spring piece is made of high-quality spring steel, subjected to strict heat treatment and specially processed, and has good mechanical properties, so that the service life of the coupling is much longer than that of the non-metallic elastic component coupling (such as elastic sleeve). Pins, nylon rod pin couplings) have grown significantly.

2. The variable load range is large, and the two toothed bearings are in contact with the reed. The tooth surface is curved. When the transmission torque increases, the spring piece will deform along the tooth surface to make the two coupling halves. The force acting on the reed is close. The contact point of the reed and the tooth surface, that is, the change of the moment, varies with the magnitude of the transmitted torque, and its transmission characteristic is variable stiffness. Therefore, it can withstand a larger load variation than a general elastic coupling. It can be seen from the following figure that the transmission force causes the cushioning effect generated when the reed is deformed along the tooth arc, especially when the machine is started or when the impact load is strong, to some extent, the safety of the supporting mechanism is protected.

3. High transmission efficiency and reliable operation The transmission efficiency of the coupling is determined to be 99.47%. Its short-time overload capacity is twice the rated torque, and the operation is safe and reliable.

4, low noise, good lubrication The aluminum alloy casing protects the spring from running out during operation, and the shell is filled with butter, which not only makes the lubrication good, but also eliminates the noise when the reed is engaged by the damping of the butter.

5, the structure is simple, easy to assemble and disassemble, the whole machine parts are small, the volume is small, the weight is light, the spring piece designed to be trapezoidal cross-section and the trapezoidal tooth groove are especially convenient and compact, so that the assembly and disassembly and maintenance are simpler than the general coupling .

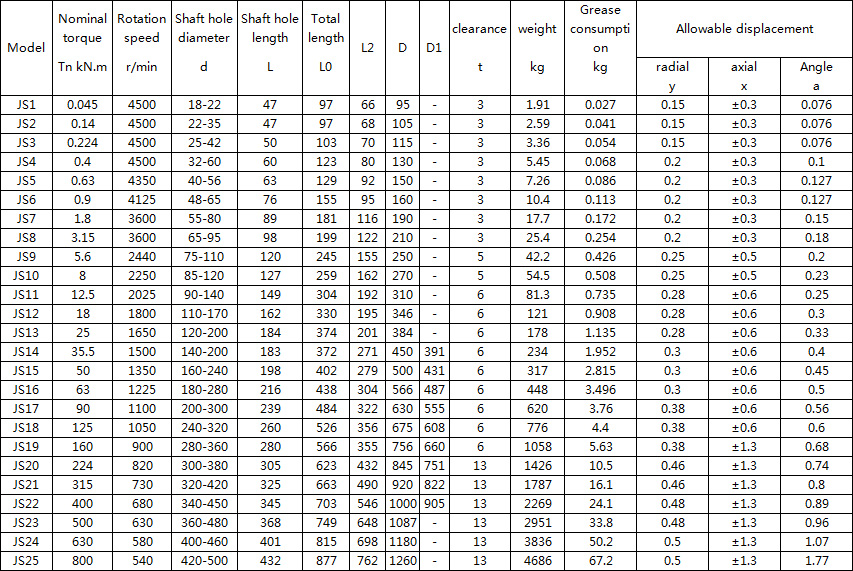

6. Allows for large installation deviation Since the spring piece is in point contact with the toothed surface, the coupling can be made more flexible. It can be installed in normal operation with radial, angular and axial deviations. The specific installation deviation values are shown in the other table.

|

Zhenjiang Haicheng Machinery Manufacturing Co., Ltd.

© Haicheng Group All rights reserved.

Address: No. 68, High-tech Development Zone, Zhenjiang City, Jiangsu Province

Service Hotline:18913433240

Company Tel: 0511-85783292 Company Fax:0511-85019680 (automatic

reception)

Copyright © Zhenjiang Haicheng Machinery Manufacturing Co., Ltd. All Rights Reserved .

Copyright © Zhenjiang Haicheng Machinery Manufacturing Co., Ltd. All Rights Reserved .

Add:No. 68, High-tech Development Zone, Zhenjiang City, Jiangsu Province Service Tell:0511-85783292