|

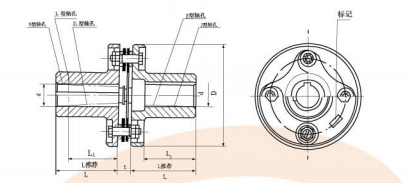

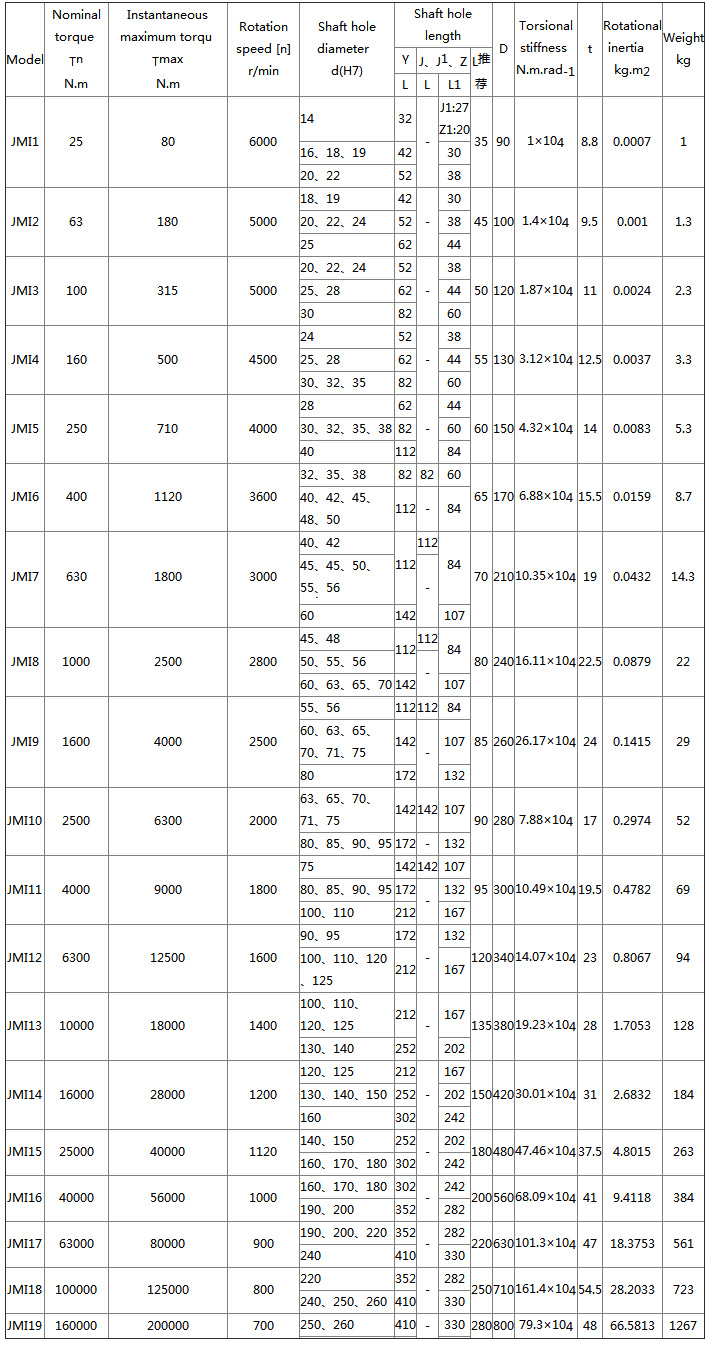

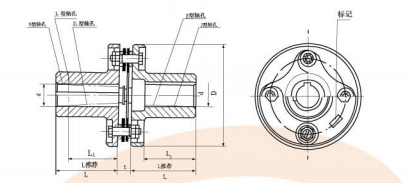

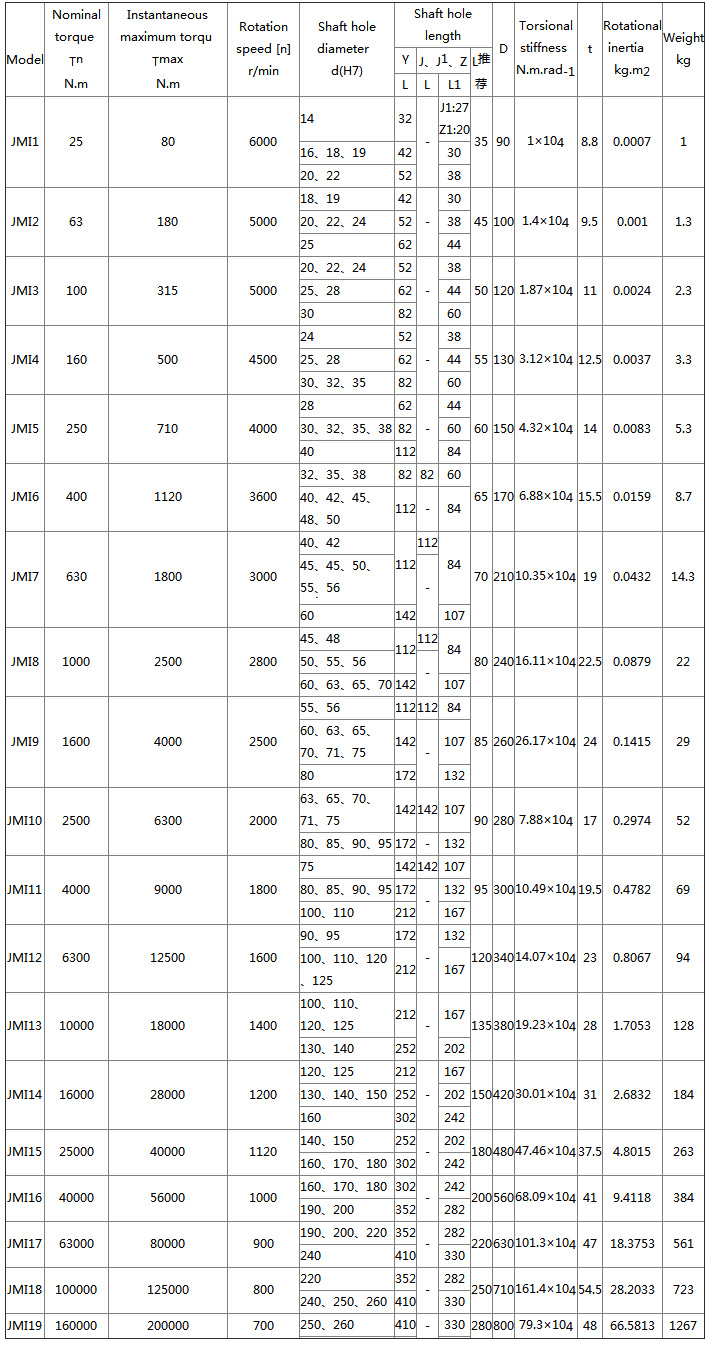

Features and application of JMI diaphragm coupling: Compared with flexible coupling of metal elastic component, it has high mechanical strength, large bearing capacity, light weight, small size, high transmission efficiency and high transmission accuracy, and good reliability. Easy to assemble and disassemble. Suitable for medium, high speed and large torque shaft drive. Compared with the drum-shaped gear coupling, it has no relative sliding, no lubrication, long service life, no noise, simple structure and so on. It can partially replace the drum-shaped toothed auxiliary device. Not affected by temperature and oil. It has the characteristics of acid resistance, alkali resistance and corrosion resistance. It can be used in high temperature, low temperature and working conditions with oil, water and corrosive media. It is suitable for shafting transmission with little change in load of various mechanical devices. It is extremely versatile and has been widely used in industrialized countries. It is a high-performance flexible coupling 重点 which is mainly promoted and applied in China. High-precision diaphragm coupling can be used for High speed conditions. Compared with the toothed coupling, the diaphragm coupling has no relative sliding, no lubrication, no sealing, no noise, no maintenance, and is convenient to manufacture. It can partially replace the gear coupling. The diaphragm coupling has been widely used in industrialized countries in the world. In practical applications, the intermediate shaft type is generally adopted to improve the offset compensation performance of the two axes. JMI type - basic type with countersink; JMIJ type--with countersunk and intermediate shaft type; JMII type - no counterbore basic type; JMIIJ type - no countersinking intermediate shaft type   |

disc coupling

disc coupling

JMI type with countersunk diaphragm coupling

Time:18-09-20

disc coupling

JMI type with countersunk diaphragm coupling

Time:18-09-20

|

Features and application of JMI diaphragm coupling: Compared with flexible coupling of metal elastic component, it has high mechanical strength, large bearing capacity, light weight, small size, high transmission efficiency and high transmission accuracy, and good reliability. Easy to assemble and disassemble. Suitable for medium, high speed and large torque shaft drive. Compared with the drum-shaped gear coupling, it has no relative sliding, no lubrication, long service life, no noise, simple structure and so on. It can partially replace the drum-shaped toothed auxiliary device. Not affected by temperature and oil. It has the characteristics of acid resistance, alkali resistance and corrosion resistance. It can be used in high temperature, low temperature and working conditions with oil, water and corrosive media. It is suitable for shafting transmission with little change in load of various mechanical devices. It is extremely versatile and has been widely used in industrialized countries. It is a high-performance flexible coupling 重点 which is mainly promoted and applied in China. High-precision diaphragm coupling can be used for High speed conditions. Compared with the toothed coupling, the diaphragm coupling has no relative sliding, no lubrication, no sealing, no noise, no maintenance, and is convenient to manufacture. It can partially replace the gear coupling. The diaphragm coupling has been widely used in industrialized countries in the world. In practical applications, the intermediate shaft type is generally adopted to improve the offset compensation performance of the two axes. JMI type - basic type with countersink; JMIJ type--with countersunk and intermediate shaft type; JMII type - no counterbore basic type; JMIIJ type - no countersinking intermediate shaft type   |

Zhenjiang Haicheng Machinery Manufacturing Co., Ltd.

© Haicheng Group All rights reserved.

Address: No. 68, High-tech Development Zone, Zhenjiang City, Jiangsu Province

Service Hotline:18913433240

Company Tel: 0511-85783292 Company Fax:0511-85019680 (automatic

reception)

Copyright © Zhenjiang Haicheng Machinery Manufacturing Co., Ltd. All Rights Reserved .

Copyright © Zhenjiang Haicheng Machinery Manufacturing Co., Ltd. All Rights Reserved .

Add:No. 68, High-tech Development Zone, Zhenjiang City, Jiangsu Province Service Tell:0511-85783292